The Knitting Process: From Yarn to Garment

-

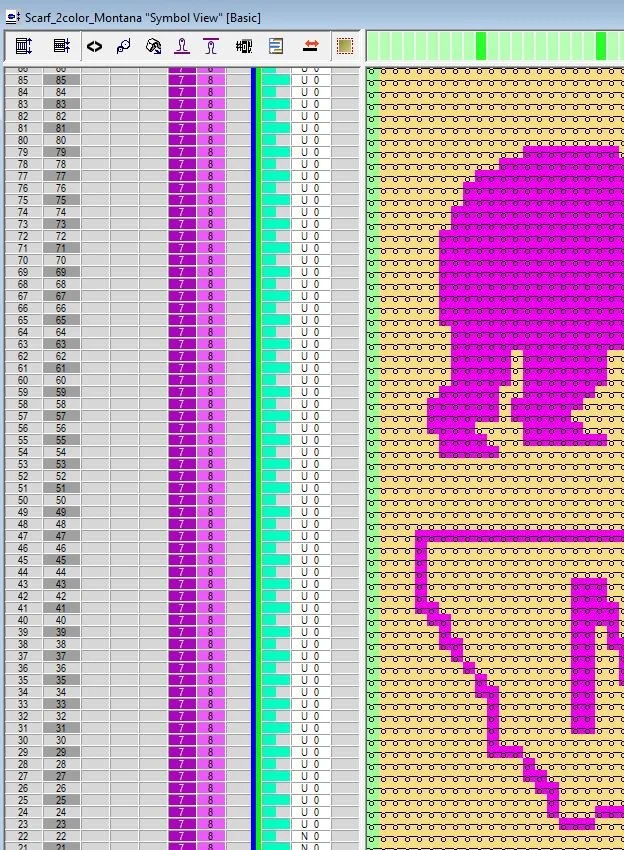

Designing

Before knitting can begin, the design is transformed to the canvas, which is a computer software specifically designed for our machine. Many steps are involved to design, program and check the pattern, stitch length, speed and many more settings to ensure the scarf will knit successfully.

-

Knitting

Based on the program created in the previous step, the yarn is placed on designated slots for the knitting machine. Here the automated machine uses sensors while traveling across the needle bed to determine which needle moves and what stitch pattern is requested. The designs are created in house and the machine can complete the tasks within 30 minutes!

-

Finishing

When the knitted garments comes off the machine, there are several manual steps required to finish the product for the consumer. Technical yarns that aid during knitting must be removed, garments are cleaned and packaged, all of which takes time.

Yarn Production: From Raw Fiber to Yarn

-

Shearing

Every year alpacas grow several pounds of fiber that is harvested by shearing the animals. The blanket, which is the main part of the back has the best fiber and is generally used for garment production. Fiber regrows every year, making this a naturally renewable resource. The following steps are generally similar across production lines, but every company has their own refined process to produce high-quality alpaca yarn.

-

Skirting & Tumbling

The raw fleece is laid out and inspected for coarse hairs and vegetable matter, which is removed manually. Next, the fiber is tumbled to help loosen more dirt that falls to the ground leaving a cleaner fleece for further processing.

-

Washing & Drying

Fiber is washed using a gentle natural soap without agitation, so as to not felt the fiber. This helps remove additional dirt, but alpaca fiber has no lanolin, so washing is only needed to remove external contaminants. Next, the fiber is again laid out flat to air dry.

-

Picking

Cleaned fiber is processed through a picker. This process opens up the locks and prepares the fiber to travel through the rollers of the carder better. Sometimes additional machines are used to remove coarse hairs to produce a better product.

-

Carding & Pin Drafting

During the carding process, the fiber travels through multiple rollers to align them in one direction, leaving one long row of fibers facing the same direction, called roving. Roving from the carder is further refined into pin-drafted roving. This step creates a more uniform and consistent roving that is stronger and better suited for machine spinning.

-

Spinning & Plying

Once the fiber is in the form of pin-drafted roving it can enter the spinner. From here, the roving is spun into the size yarn that is desired, from very thin to thicker. After a single strand of yarn is done, these are then plied together to make the finished yarn. Finally, the yarn is wound on cones which are used for machine knitting.